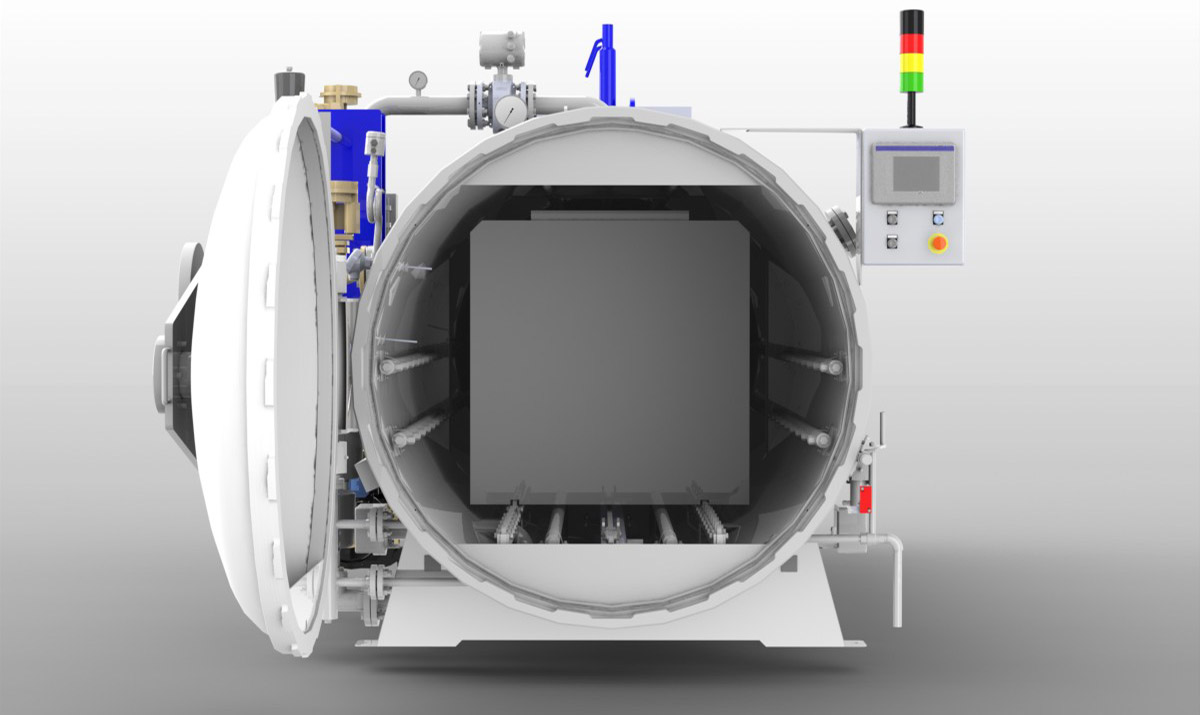

Smart Post-Pack Sterilizers

Surdry’s latest equipment development program includes the concept of “smart” to describe post-pack sterilizers (batch and continuous) ready:

SteriNet21

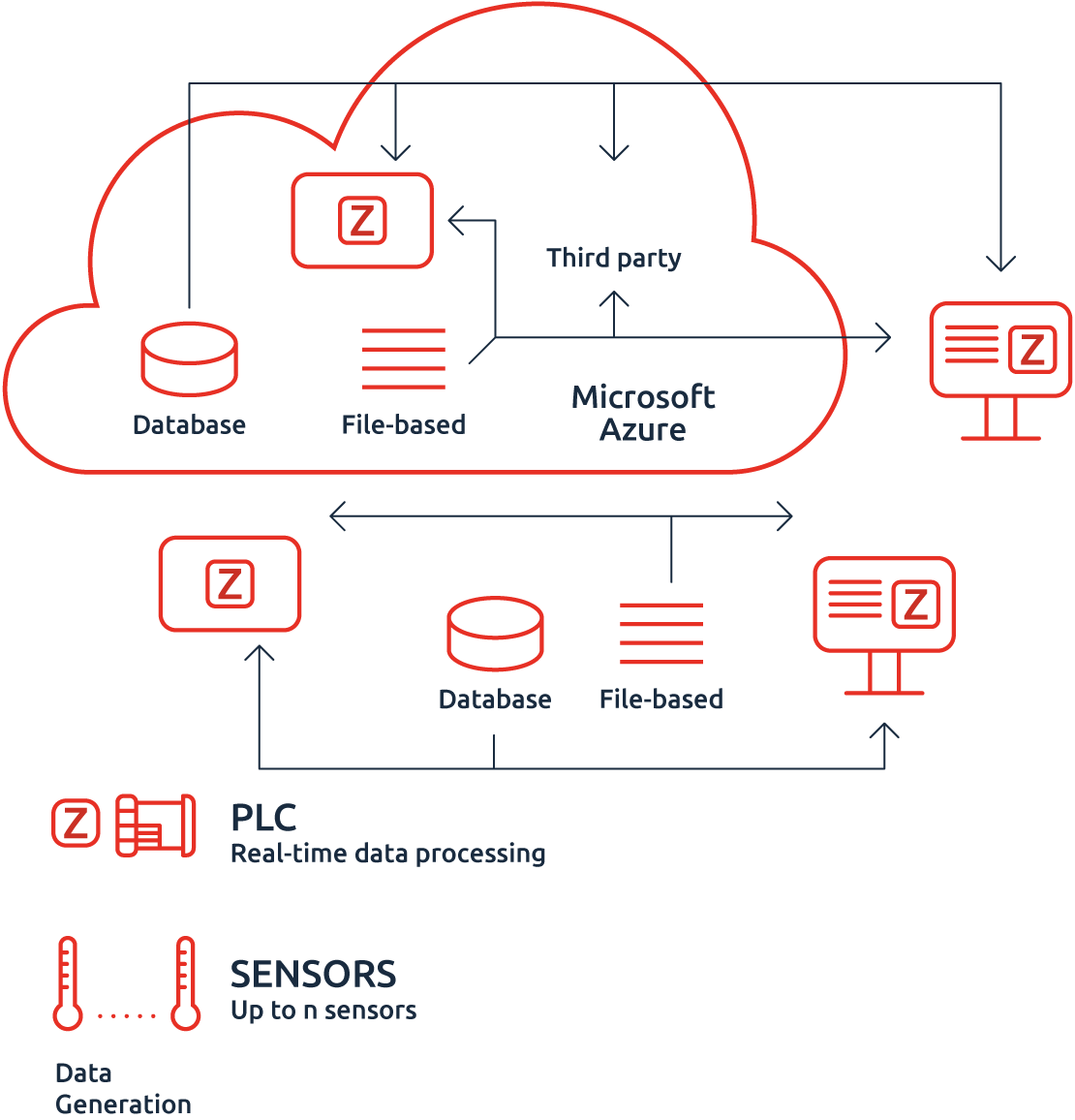

Surdry has modernized the control system with new functionalities in a user-friendly and intuitive environment. With the new name of SteriNet21, it replaces SteriNet for more connectivity and better remote service.

SteriNet21 has been developed by Surdry IT experts using Rockwell Automation and Copa-data Zenon hardware and software.