Surdry Process Technology

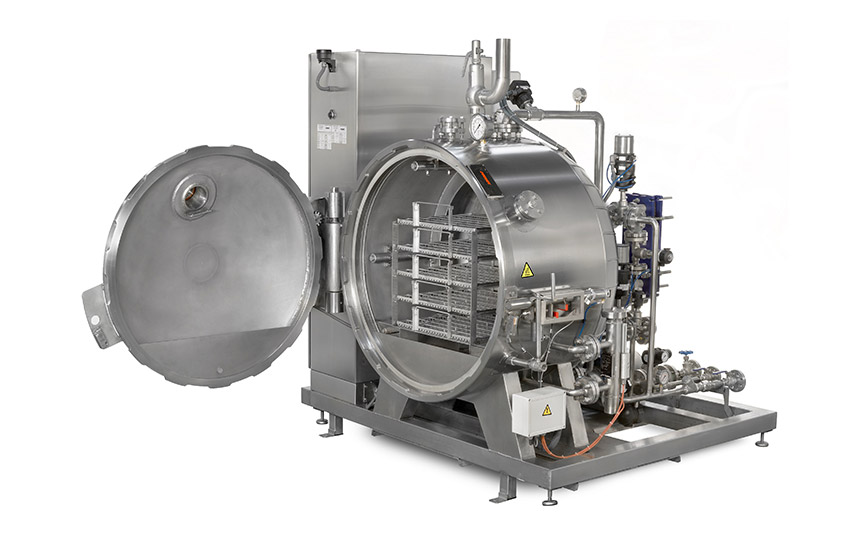

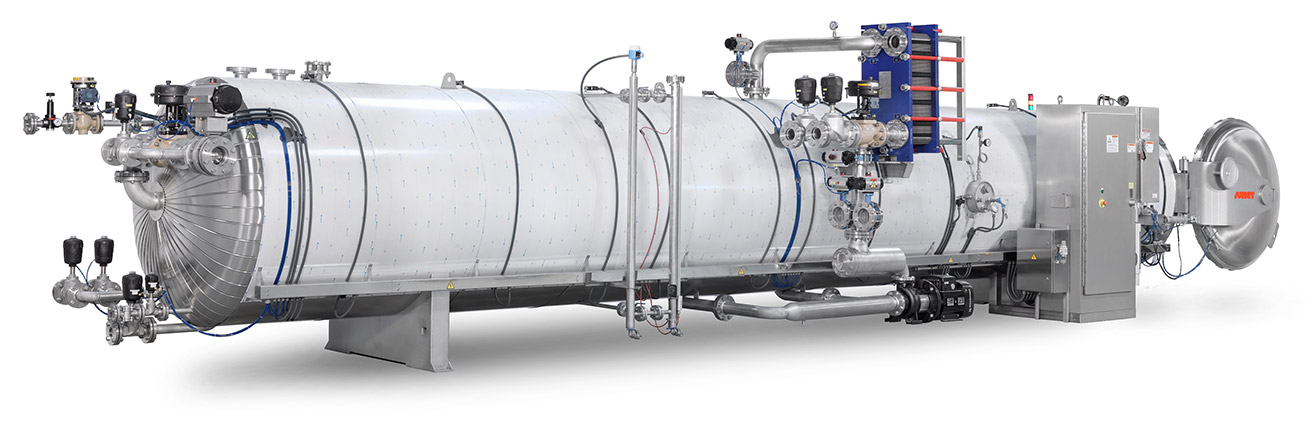

Models with horizontal and vertical doors are available in diameters ranging from 950 mm up to 1800 mm with chamber lengths up to 10 mts, to take up to 8 baskets. Surdry has standardized the A-14X-SWS series (1400 mm diameter and X for up to 8 baskets) to provide quicker delivery and competitive pricing.

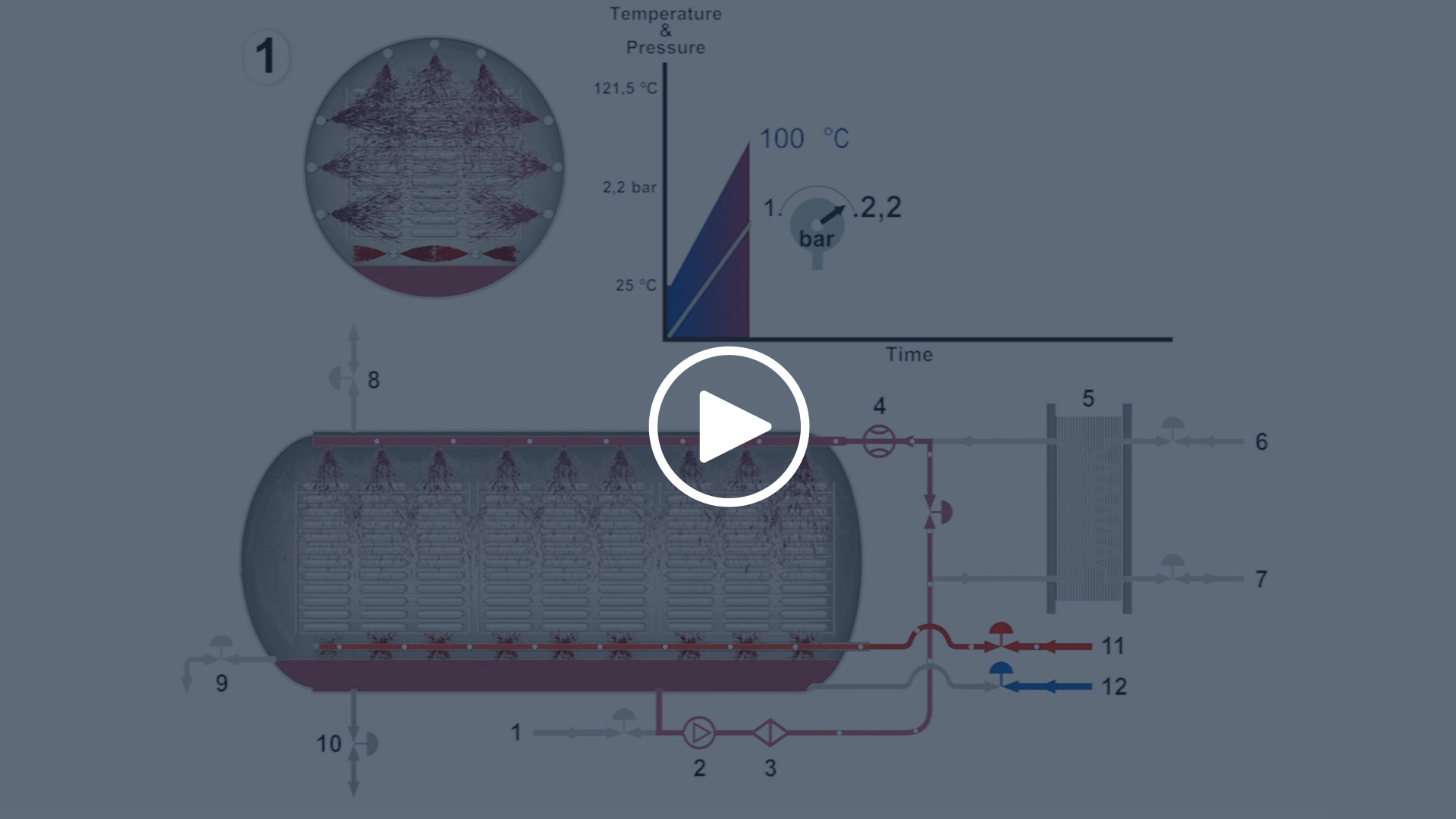

SWS, standing for Steam and Water Spray mixture is acknowledged to be the technology that best suits any type of food container. Other technologies like SST, Hybrid and WSH technologies are also available in this wide range.

Smart Production Retorts

Intelligent and Connected

Static A-XY

Reliable Sterilization Made Simple

Rotary AR-XY: Rotary or high angle of oscillation

Full Rotation and High Angle Oscillation

Oscillating A-XY-OS

15º Angle Oscillation with High Load Capacity

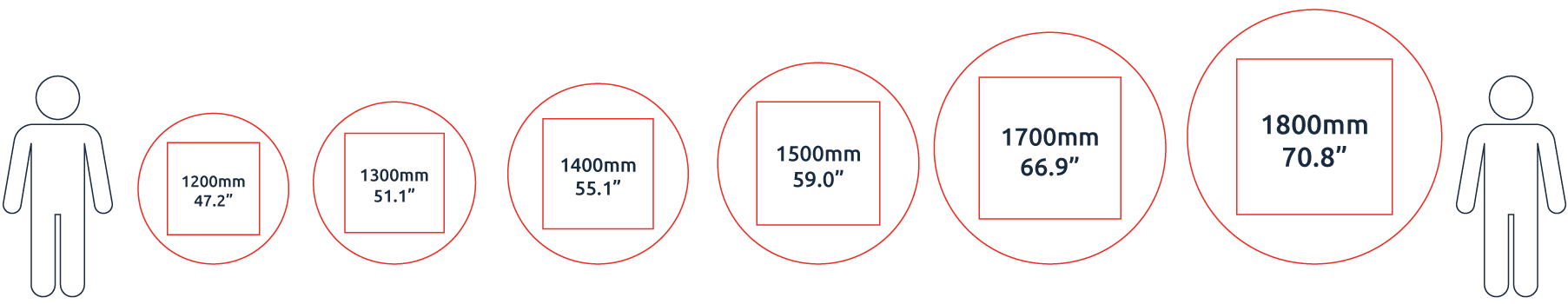

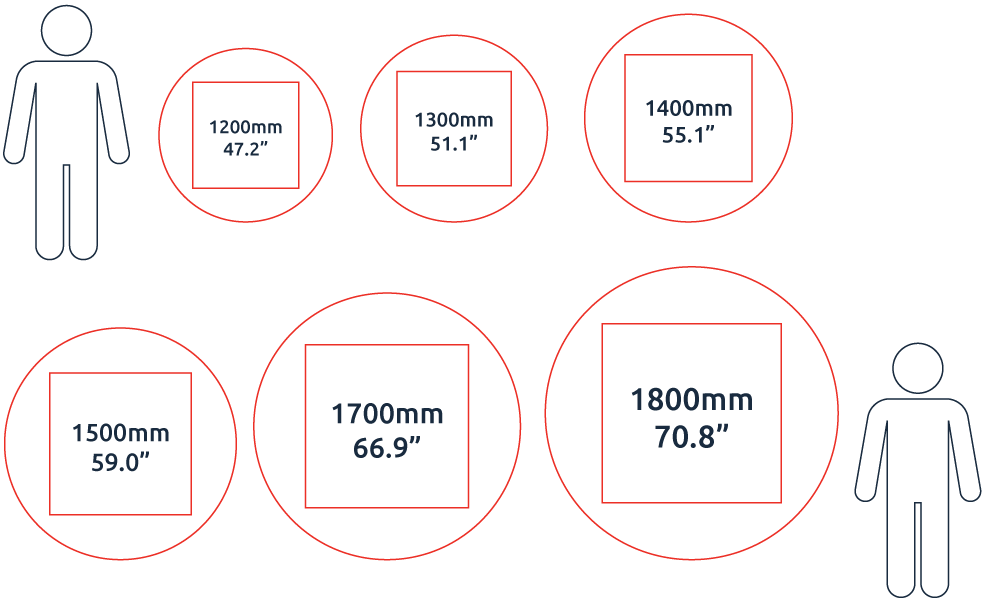

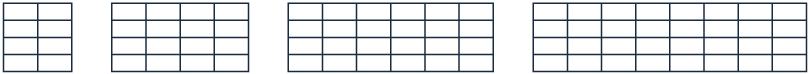

Wide range of retort

diameters and lengths

Regular production models

1200mm

47.2”

1300mm

51.1”

1400mm

55.1”

1500mm

59.0”

1700mm

66.9”

1800mm

70.8”

1800mm

70.8”

1800mm

70.8”

1800mm

70.8”

1800mm

70.8”

1800mm

70.8”

1800mm

70.8”

Lengths from 1 to 10 mts, 1 to 8 baskets

Control systems

Surdry’s control systems team is integrated by professionals with more than 20 years in the company, together with talented specialists in programming and installation of PLC, HMI and SCADA systems.

SteriNet21, the latest control system release, features secure operation and high data protection in compliance with FDA Regulation Title 21 CFR Part 11. State-of-the-art visual tools enable easy and intuitive navigation and operation.

Surdry relies on Rockwell Automation and Copa-Data to create robust and smart hardware and software combinations.

Handling Systems Automation

In partnership with well-known international specialists Surdry, helps the customer to choose the handling equipment that best suit their operation requirements. A good handling system choice and plant layout is essential for operator safety as well as for process safety. Nobody wants their staff injured or any unsterilized products by-passing the retorts.